India is still young, vibrant, and evolving—its ambitions stretching as far as its horizons. Every day, the nation grows stronger, driven by an unshakable vision of progress. At the heart of this journey stands Renny, a leading pillar of India’s in structural green steel solutions infrastructure growth, committed to building not just projects, but futures.

Structural Strength for a Growing Nation

From towering commercial complexes to resilient bridges, from expansive industrial plants to smart cities, India’s development story is written in steel. Renny’s wide range of structural green steel solutions is engineered to power this transformation—offering unmatched strength, durability, and sustainability.

Our diverse product portfolio includes:

- Scaffolding & Formwork Systems – Ensuring safe, efficient, and precision-built construction.

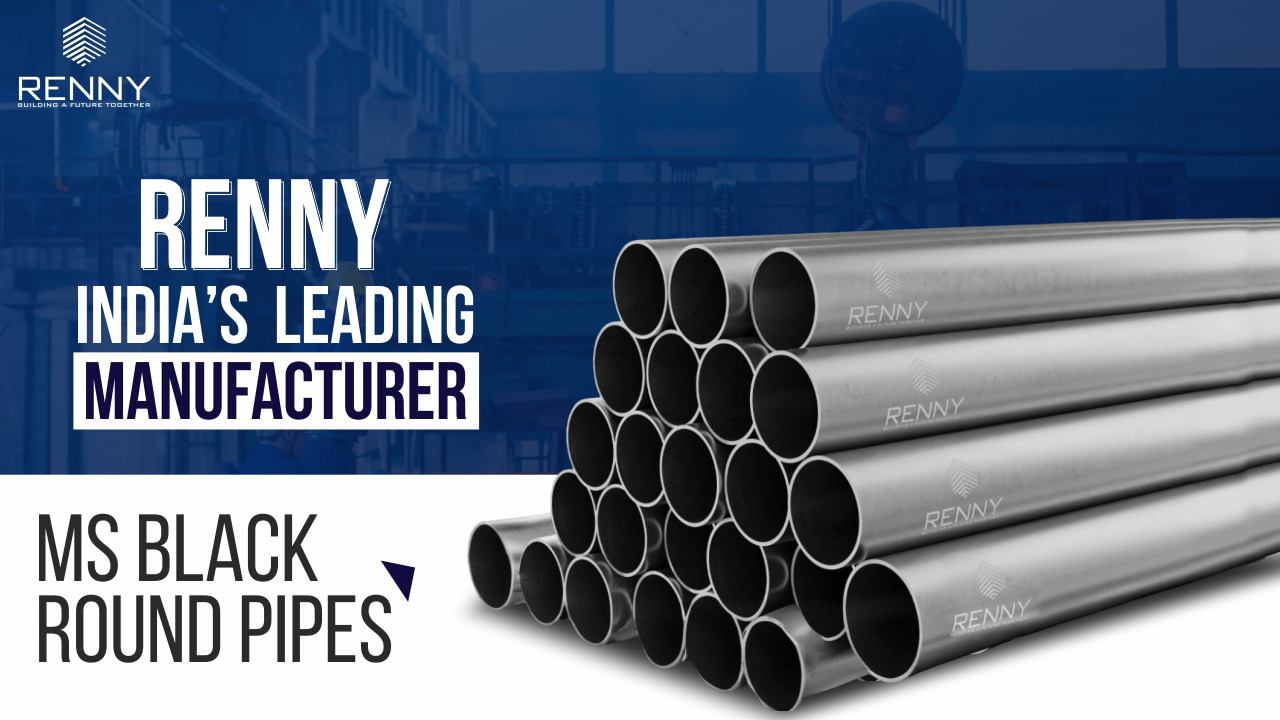

- ERW Pipes – Engineered for structural, industrial, and infrastructure applications.

- Narrow HR Coils – Ideal for precision forming and downstream manufacturing.

- Wire Rods – High-strength, versatile raw material for engineering and industrial use.

- Forging Billets – Premium-quality billets for high-performance forged products.

Applications Across Industries

Renny’s products power some of the most demanding sectors in India and beyond:

- Construction & Infrastructure – High-rise buildings, bridges, metro projects, industrial complexes.

- Oil & Gas – Pipeline networks, structural supports, offshore platforms.

- Manufacturing & Engineering – Automotive parts, machinery components, fabrication units.

- Energy – Power plants, transmission towers, renewable energy structures.

- Transportation – Railways, shipbuilding, heavy equipment manufacturing.

This comprehensive range allows Renny to serve as a one-stop steel solutions provider, supporting India’s growth at every stage.

Sustainability at the Core

As the nation advances, so does the urgency to protect our environment. Renny’s green steel manufacturing integrates low-emission production technologies, energy-efficient operations, and circular economy practices—delivering steel with up to 75% lower CO₂ emissions compared to conventional production. This significant reduction ensures that progress does not come at the cost of the planet, setting a new benchmark for responsible manufacturing in the steel industry.

♻ Sustainability Impact at a Glance

| Impact Area | Renny Green Steel Advantage |

| Carbon Footprint | Up to 75% lower CO₂ emissions than conventional steel manufacturing. |

| Energy Efficiency | Advanced, energy-optimized production lines. |

| Circular Economy | High scrap recycling rate & waste reduction initiatives. |

| Resource Conservation | Water reuse systems & raw material optimization. |

| Global Compliance | Meets ISO, EN, and CBAM sustainability standards. |

Empowering Communities Beyond Steel

Our commitment extends beyond manufacturing excellence. Renny is a driver of employment generation, offering opportunities that empower individuals, uplift families, and strengthen communities. Through skill development initiatives, workplace safety programs, and fair employment practices, we create a workforce ready to meet the demands of a modern, industrial India.

Building a Better Tomorrow Together

Development isn’t only about roads, bridges, and buildings—it’s about people. That’s why Renny actively invests in community development projects, from education and healthcare to infrastructure that improves quality of life. We believe that the true measure of progress lies in the well-being of our people and the resilience of our communities.

Renny: The Steel Behind the Story

Every great nation needs strong foundations. Renny stands as a trusted partner to India’s growth, delivering steel solutions that shape skylines, connect cities, and drive industries—while keeping sustainability, innovation, and social responsibility at the forefront.

The future is bright, and India’s story is still being written. With Renny, every chapter is built on strength, sustainability, and shared prosperity.