Renny Strips was established in 1996 under the leadership of Mr. Dev Gupta and Mr. Binny Gupta. Headquartered in Ludhiana, the company is renowned for its innovative, sustainable and industry-fit steel products. Renny specializes in four key divisions:

Coil Division: Produces premium quality HR coils.

Pipe Division: Manufactures MS Black & Galvanized Hollow Sections in various shapes.

Scaffolding & Formwork Division: Offers a one-stop solution for scaffolding and formwork with specialized products.

Industrial Paint Division: Rapidly gaining traction for its quality and competitive advantages.

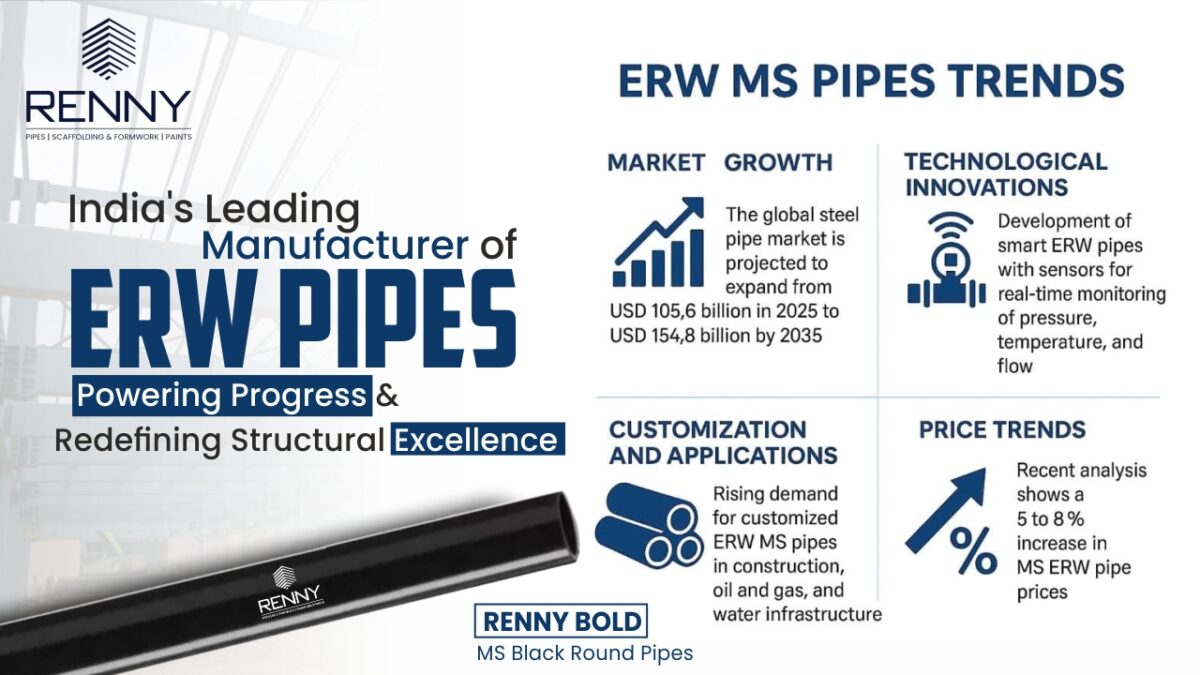

With 3 state-of-the-art integrated facilities in Punjab and a production capacity of 300,000 MTPA, Renny maintains over 1,000 SKUs, establishing itself as a leading ERW Pipes & Tubes, Formworks & Scaffolding manufacturer in North India. The company serves both national and international markets through a strong distributor network and adheres to stringent industry standards with certifications like ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 & EN 1090-2:2018.

Shaping a Sustainable Future with Green Solution in Structural Steel Building

Renny, a pioneer in Green Steel Manufacturing, is dedicated to advancing sustainability through the principles of Reduce, Reuse and Recycle. By reducing Carbon Emissions by 1.6 tons per ton of steel produced and deploying a 22 MW Solar Energy Plant, Renny Strip’s carbon emission is 50% lesser than the competitors. The company has achieved a 75% reduction in energy consumption, cut Greenhouse Gas Emissions by 86%, and controls 70% of Water Contamination through conservation and treatment efforts. Additionally, Renny promotes a Circular Economy through effective Waste Management and enhances environmental sustainability by expanding Green Cover in collaboration with the Department of Forest, Punjab and the National Highway Authority.

Innovation & RD

Renny Industries is transforming the structural steel market through cutting-edge innovation, replacing traditional materials like wood and aluminum with advanced steel solutions. Their extensive portfolio includes critical components such as channels, angles and beams, continually setting new industry standards with sustainable and innovative offerings. With over 1,000 SKUs and more than 10 research programs focusing on corrosion resistance, durability, bendability, weldability and fatigue resistance, Renny elevates product performance and longevity. The state-of-the-art facilities and R&D centers are dedicated to pioneering sustainable manufacturing practices aligned with UN SDGs.

Renny Bold

Renny producing Renny Bold in Black Round Pipe Range, using HR coils tied with advanced manufacturing techniques, ensuring exceptional durability and strength that meet industry standards. These pipes are designed for superior performance and longevity, catering to a wide array of industrial applications. Known for their ease of Welding, (text removed) Black Bold pipes are available in 33 OD to 127 OD (mm) with thickness 1.4mm to 5.5mm & maintain the standard of IS:1239:2004(Part-1) &1161:2014, 3601:2006.

The versatility of Renny Bold range makes these pipes suitable for multiple applications, including Liquid Transmission, Firefighting, Scaffolding, Structural Applications & General Engineering. With exceptional strength, these pipes can withstand heavy load, stress and external influences, making them perfect for demanding fabrication projects. Their robust construction ensures the stability and safety of structures, providing long-term reliability.

Renny Hero

Introducing Renny Hero, specialized High-Strength Hollow Sections, meet rigorous manufacturing standards, combining lightweight design with exceptional Resilience against Seismic Forces. Available in standard & customizable sizes for Square Hollow Section (SHS) 25×25 to 100×100 & (comma removed) Rectangular Hollow Sections (RHS) 40×20 to 122×61 in thickness of 1.4 to 5.5 (mm). Renny Hero maintains the standard of IS: 4923:2017 & IS: 18573:2024 & offers unmatched Flexibility, Durability, Efficiency & Cost-Effectiveness in ERW Pipe & Tube Production.

Renny Hero meets diverse industry needs, encompassing Architectural, Industrial & Infrastructural Applications. It also supports General Engineering & Agricultural Sectors, offering versatile solutions for a wide range of Applications & Implementations.

Renny Guard

Renny presents Renny Guard, a unique range of GI pipes crafted from high-performance, Renny follows the Hot Dip Galvanizing process with the minimum zinc coating of 385 GSM zinc coating. These pipes offer versatile Circular, Square & Rectangular Hollow Sections, perfect for use in highly humid and coastal regions, available in CHS (33 OD to 127 OD), SHS (25X25;100X100) RHS (40X20;122X61) with the Thickness of 1.4 to 5.5 (mm).

Renny Guard Gi Pipes offer Unbeatable Durability & Structural Excellence, featuring Unparalleled Strength through Advanced Technology & Strict Industry Standards. Fully galvanized with zinc, these Rust-proof Pipes & Tubes are highly Resistant to Corrosion, making them ideal for Harsh Environments. Their inherent ability to withstand high temperatures provide a Natural Barrier against Fires. The Termite-Resistant qualities ensure long-lasting protection against pests. Engineered for diverse structural needs, Renny Guard range is the top choice for Solid Building Foundations & Increased Structural Integrity across various applications.

Advanced galvanization techniques enhance their corrosion resistance, making the Renny Guard GI range ideal for Oil & Gas, Firefighting, Irrigation, Infrastructure, Scaffolding & Formwork (word added) & Industrial Applications that demand rigorous Fabrication.

RSP (Renny Scaffolding Pipes)

Renny proudly presents RSP, the highest quality round pipes specifically designed for scaffolding fabrication. Bespoke grade specifications are adhered to by Renny to meet customer demands, ensuring superior quality & performance.

RSP is available in two variants, which include Roll Thread Pass Pipe & Scaffolding Pipe. The Roll Thread pass pipes are available with smooth threading for easy assembly & enhanced construction efficiency.

Scaffolding pipes in various available (text added) finishes, including Black, GI, GP & Color Coated. These pipes are hot-rolled into round size like, 38.1OD, 48.3OD 60.3OD.76.1OD (mm) in various thickness. Marinating the Standard of (BS1139, EN39, EN10219). RSP comes with specialized products as per requirement for versatile construction applications. High production stan+0ards and top-notch quality are ensured by Renny’s expert team, making RSP a reliable solution for scaffolding needs with a versatile array of props. RSP caters the applications in Construction, Infrastructure, Welding, Painting & Plastering, Ship Building, Oil & Gas Industries etc.