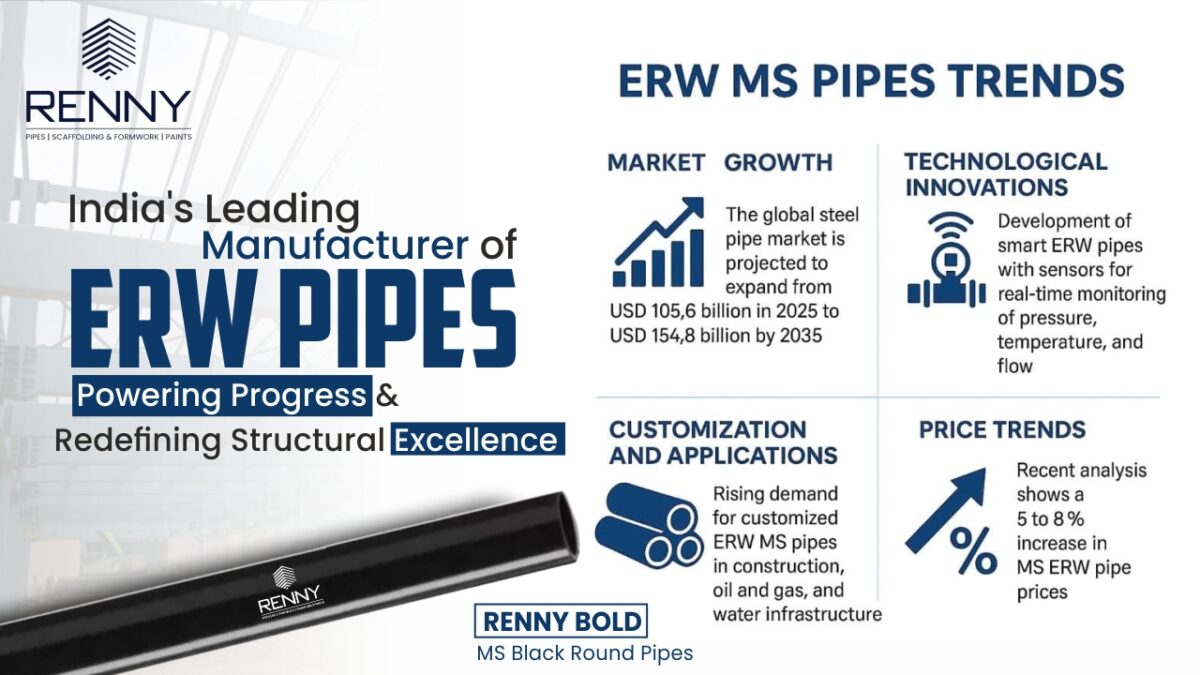

Global Trends in ERW MS Black Pipes

As the infrastructure, construction & manufacturing sectors surge globally, the demand for high-quality ERW MS (Mild Steel) Black Pipes is stronger than ever. From skyscrapers and industrial sheds to pipelines and machinery, these pipes are the backbone of countless engineering and structural applications. Amidst this global demand, choosing the right manufacturer is critical. Enter Renny Strips—a trusted name known for delivering excellence in every pipe.

The Global ERW MS Pipe Market: A Quick Overview

The global market for ERW mild steel pipes is witnessing robust growth, projected to reach over 107 million tons by 2030, growing at a CAGR of ~5.9%. This expansion is driven by increased investment in infrastructure, urbanization in emerging economies, and the revival of oil & gas projects. In this dynamic scenario, India is emerging as a key player, and Ludhiana, Punjab, is at the heart of this transformation.

Why MS Black Pipes are in High Demand

MS Black Pipes, especially round ones, are widely used due to their:

- High strength-to-weight ratio

- Excellent weldability and machinability

- Cost-effectiveness for structural and fabrication needs

- Versatility in construction, scaffolding, fluid transportation, and industrial usage

However, not all pipes are made equal. Quality, consistency, and standard compliance determine performance and longevity—and that’s where Renny Strips stands out.

Renny Strips: The Premium Manufacturer of MS Black Pipes in India

At Renny Strips, we take pride in being one of the leading manufacturers of MS Black Pipes in India, backed by decades of expertise and engineering excellence. We have a strong footprint in Ludhiana, Punjab, where our operations are driven by innovation & precision.

Renny is recognized as the best manufacturer of MS Black Pipes in Ludhiana, Punjab, with an integrated plant infrastructure supported by three strategically located units across the region. This allows us to maintain seamless production, optimize logistics & ensure consistent quality.

Our MS Black Pipes are marketed under the brand Renny BOLD—a trusted name known for strength, precision & performance. We source premium raw material in-house, enabling full control over quality, cost & consistency. Every pipe undergoes stringent quality checks, ensuring compliance with industry standards.

With on-time delivery, competitive pricing, and a commitment to excellence, Renny Strips continues to power projects across India with pipes that are built to endure and engineered to perform.

Why Choose Renny BOLD MS Black Round Pipes?

- Premium Quality:Crafted from hot rolled (HR) coils, our black pipes ensure high durability, perfect roundness, and smooth surface finish.

- Precision Manufacturing:Available in 33 mm to 127 mm Outer Diameter (OD) with 1.4 mm to 5.5 mm thickness, ideal for a wide range of applications.

- Industry Compliance:Manufactured using advanced ERW technology, Renny BOLD pipes are compliant with national and international standards.

- In-House Integration:With 99% raw materials produced in-house, we ensure complete control over quality and supply chain efficiency.

- Proudly Made in Ludhiana:As a proud Punjab-based manufacturer, Renny is driving regional growth while serving national & international markets.

Applications of Renny BOLD MS Black Pipes

- Structural steel frameworks

- Scaffolding and formwork systems

- Agricultural and industrial water transport

- Solar panel and windmill foundations

- General fabrication and engineering works

Renny Strips: Setting New Standards in ERW Pipe Manufacturing

With a deep commitment to innovation, quality, and sustainability, Renny Strips has emerged as a market leader in ERW MS Pipe manufacturing. Our integrated facility in Ludhiana is equipped with state-of-the-art ERW mills, stringent quality control systems, and a team of experts that drive continuous excellence.

Whether you’re building a mega structure or laying the foundation for an industrial unit, Renny BOLD MS Black Pipes provide the strength, reliability, and precision your project deserves.

Choose Renny. Choose Reliability.

When quality matters, Renny Strips is the right choice. Our MS Black Round Pipes deliver unmatched performance, making us the trusted partner for countless builders, fabricators, and industrial users across India and beyond.

Renny BOLD – Engineered to Endure. Built to Perform.