With so many options in the market, choosing the right ERW pipes and tubes can be overwhelming. From ensuring material strength to verifying certifications and compliance, every decision can impact the success of your project. But Rennystrips eliminates the guesswork by offering a diverse, high-quality, and globally compliant range of ERW pipes and tubes tailored for performance in any application.

Renny’s wide product portfolio, backed by decades of expertise and stringent testing, ensures that clients receive only the most reliable solutions, whether for construction, fabrication, automotive, agriculture, or heavy engineering industries.

At a time when consistency and environmental consciousness are more important than ever, Rennystrips stands apart with its 99% in-house raw material production. This level of vertical integration ensures complete control over quality and traceability, giving clients confidence in every delivery. From raw material to final product, everything is manufactured under one roof at Renny’s advanced integrated plant in Ludhiana, Punjab — making it the top choice for anyone searching for ERW pipes and tubes near me or reliable ERW pipe manufacturers in India.

But Renny’s story isn’t just about superior manufacturing — it’s about raising the bar in every aspect. Every ERW pipe and tube produced by Renny is subject to stringent quality checks, not only through traditional methods but also through modernized inspection technologies. The result? A product that adheres to both domestic and international standards, backed by certifications like EN 1090-2:2018, ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, CE, and the prestigious TÜV Rheinland certification for advanced welding. When engineers and project managers specify Renny ERW pipes, they’re choosing reliability that’s recognized across the globe.

What truly makes Rennystrips a future-forward manufacturer is its commitment to sustainable production. In an industry often criticized for its environmental impact, Renny is rewriting the narrative by reducing carbon emissions by 75% compared to competitors. Fully compliant with CBAM regulations, Renny’s processes reflect global climate priorities. And it doesn’t stop there. With a powerful 22MW solar plant powering much of its operations, Renny is proving that industrial strength can come with a green footprint.

Choosing Renny ERW pipes isn’t just good for your project — it’s also good for your bottom line. The company’s 360-degree sustainable manufacturing approach provides clients with up to 72% in tax benefits, a value-added advantage that few in the industry can offer. With competitive pricing, lower emissions, and top-tier quality, Rennystrips is quickly becoming the go-to name for businesses that care about both performance and planet.

So, whether you’re building infrastructure, leading fabrication, or launching industrial projects that demand precision and durability, Rennystrips ERW pipes and tubes are the ultimate choice. In a market filled with options, Renny leads not only with its products but with its principles — quality, sustainability, and excellence, every step of the way.

Experience the strength of innovation. Choose Rennystrips — the best ERW pipe and tube company in India.

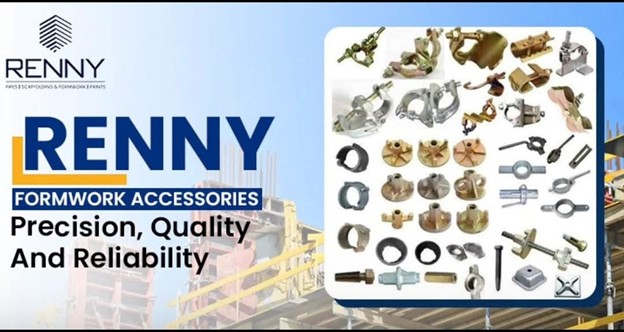

Our Brands | Renny Bold | Renny Hero | Renny Guard |

RSP

|

MS Black Round | Hollow Section (SHS & RHS) | Galvanised Pipe | Renny Scaffolding Pipe | |

Size Range | 33–127 mm OD, SHS 25×25 to 100×100 & RHS 40×20 to 122×61 | |||

Thickness Range | 1.4–5.5 mm | |||

Standards | IS: 1239:2004, IS:1161:2014, IS:3601:2006, IS: 4923:2017, BS1139, EN39, EN 10219 | |||

Grade | YST 210, YST 240, YST 310, YST 355 | |||

Surface Finish | Black, GI, Color Coated & Roll Thread Pass | |||

Applications | Liquid Transmission, Firefighting, Scaffolding, Structural & General Engineering | |||